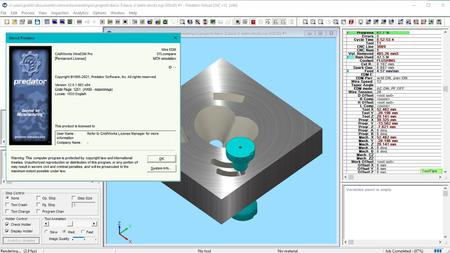

CAMWorks WireEDM Pro 2022 SP0 | 953.5 mb

Product:CAMWorks WireEDM

Version:2022 SP0 build 29-August-2022 for SolidWorks

Supported Architectures:x64

Website Home Page :www.camworks.com

Languages Supported:multilanguage

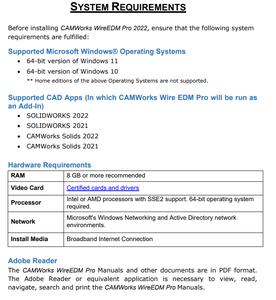

System Requirements:Windows *

Size:953.5 mb

Languages Supported: English, Deutsch, Español, Čeština

GeometricPLM is pleased to announce the availability of WireEDM Pro 2022 SP0 build 29-August-2022 is the world’s most advanced wire EDM programming tool.

New in CAMWorks WireEDM Pro 2022 SP0

Download a PDF of this content, CAMWorks WireEDM Pro 2022 SP0 Release Notes Documentation:

1. CWE-625 CSR-20509 The WireEDM Electrical conditions for rough cuts in coreless machining are not getting output with specific customer post files are used for post processing.

2. CWE-623 CSR-20505 For the specific operation generated for the specific part, if the ‘Save to TechDB’ command is executed twice, it causes the WireEDM Pro application to crash.

3. CWE-619 — When WireEDM Pro application is used to program any part, a temp file gets created and left in the folder containing the part file. The temp file does not get auto-deleted even after the part file is closed. This inconveniences many users.

4. CWE-617 CSR-20362 For the specific part machined using WireEDM Pro application, user is unable to correctly set the start points for top and bottom wire associated with the toolpath generated for machining a long horizontal edge.

5. CWE-616 CSR-20382 When the Wire Start Point of a 2 Axis toolpath generated for a specific part is edited, it is observed that the bottom of the wire starts at thenew position, but the top of the wire still starts at the original position.

6. CWE-574 CSR-19976 In WireEDM Pro 2021 SP2 version, when the Forced Rebuild command is executed for a programmed part, it is observed that the machining side switches from the original left side to right side resulting in gouging of the part.

7. CWE-562 CSR-19698 For many parts, the depths of the toolpaths generated for machining the features do not match the actual depths of those features. These incorrect depths cannot be corrected within the application

8. CWE-557 CSR-19591 When the specific part is rebuilt and machined on a CHMER G machine, the post processed code contains VB errors.

9. CWE-556 CSR-14920 The toolpaths generated for Rough Coreless operation in WireEDM Pro application do not consider the CNC compensation and offset.

10. CWE-470 CSR-18480 In WireEDM Pro application, within the EDM Setup, the "Project 3D Shapes" parameter in the Parameters list is not available. However, the Help menu mentions the presence of this parameter.

11. CWE-458 CSR-18131 For the specific part with a tapered cylindrical face with grooves on the top of that faces, the WireEDM Pro application fails to generate a 2 Axis toolpath.

12. CWE-447 CSR-17695 The WireEDM Pro Installation Guide specifies that the Windows 7 OS is supported. However, only Windows 10 OS is supported.

13. CWE-432 CSR-17390 For the specific part for which a SOLIDWORKS coordinate system has been assigned as origin, the origin is graphically displayed at an incorrect location thereby leading to incorrect display of stock and wire movement during simulation.

14. CWE-411 — A mechanism must be made available within the WireEDM Pro application whereby users are visually provided feedback on operations for which no associated toolpaths are generated.

15. CWE-389 CSR-16934 For the specific part, every time the Rebuild command is executed, the side of cut in toolpath keeps getting flipped.

16. CWE-386 CSR-16852 The WireEDM-Toolpath breaks down on small arcs which measures 0.0005 Inches or smaller.

17. CWE-280 CSR-15901 During simulation of the specific part, if the Tool Animation speed is set to ‘Fast’ or ‘Medium’, then the system doesn’t Chip Removal to removethe die from the stock.

18. CWE-251 CSR-15575 For the specific part, when the Recognize / Find Pattern option is active, features are recognized incorrectly and SOLIDWORKS crashes when attempting to close/save the part.

19. CWE-243 — For the specific part, the 4 Axis toolpath generated for the feature with spline geometry is incorrect

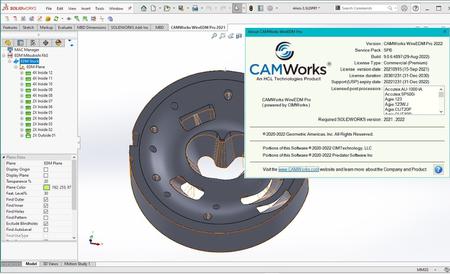

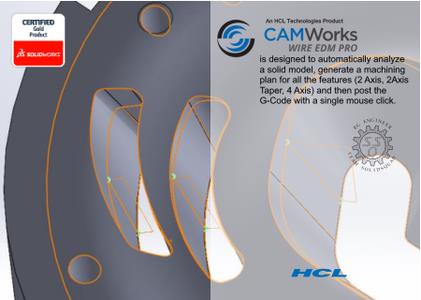

CAMWorks WireEDM Prois a newly introduced application in the CAMWorks suite of software products. It is a culmination of over 30 years of specialization in Wire EDM CAM technology. CAMWorks WireEDM Pro is seamlessly integrated to work as an Add-in within the SOLIDWORKS/CAMWorks Solids CAD applications. It is designed to automatically analyze a solid model, generate a machining plan for all the features (2 Axis, 2 Axis Taper, 4 Axis) and then post the G-Code with a single mouse click! It applies the cutting technology of your Wire EDM machine to the geometry of the solid model to be machined to generate the best possible G-code for your machine. This functionality allows you to take full advantage of all the latest cutting improvements in the field of Wire EDM technology.

CAMWorks Wire EDM Pro will be an ideal choice for firms working with machining solid part models using WireEDM CAM technology.

Take your Wire EDM programming to the next level with the all new CAMWorks Wire EDM Pro

GeometricPLM by HCL Technologiesa specialist in the domain of engineering solutions, services and technologies. Its portfolio of Global Engineering services, Product Lifecycle Management (PLM) solutions, Embedded System solutions, and Digital Technology solutions enables companies to formulate, implement, and execute global engineering and manufacturing strategies aimed at achieving greater efficiencies in the product realization lifecycle.

On April 1st 2016, Geometric got into an agreement with HCL Technologies to transfer of its business to HCL Tech by way of demerger, except for its 58% share in the joint venture with Dassault Systèmes (3DS) (3DPLM Software Solutions Limited (3DPLM)). The transition has become effective on March 2nd 2017, after seeking all statutory approvals.

Download From UploadCloud

DOWNLOAD FROM UPLOADCLOUD

DOWNLOAD FROM UPLOADGIG.COM

DOWNLOAD FROM RAPIDGATOR.NET

DOWNLOAD FROM NITROFLARE.COM